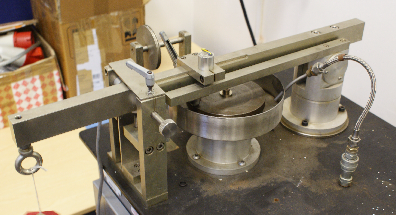

Eyre/Biceri Wear Machine

-

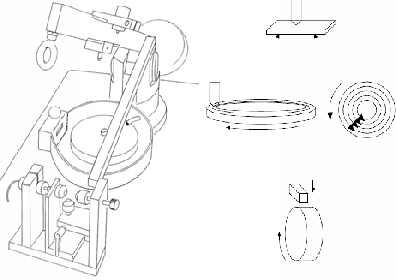

The Eyre/Biceri Universal Wear Machine is a versatile tool for evaluating the wear and friction characteristics of materials, surface finishes, treatments and lubricants. It is suitable for testing materials, ceramics, plastics, dry lubricant coatings, surface hardening coatings, lubricants and additive packs. The standards machine is a Pin-on-disc unit, however other modules allow operation in a Pin-on-Reciprocating plate or block-on-ring mode. The speed, load, and temperature can be controlled independently, enabling a wide range of operating conditions to be studied.

-

The unit comprises a cabinet fitted with top module mounting plate and a variable speed drive system mounted within. The standard Pin-on-disc shaft assembly transmits motive power for all three modes of operation. With each mode facilitated by the addition of an appropriate module located on the top plate. A dead weight load arm is used to load test samples, and a force post assembly measures wear and friction coefficient.

-

Wear and friction is measured with two transducers whose output is plotted directly on a suitable recorder or collected on the computer system. Software is available for the data collection and enhanced presentation